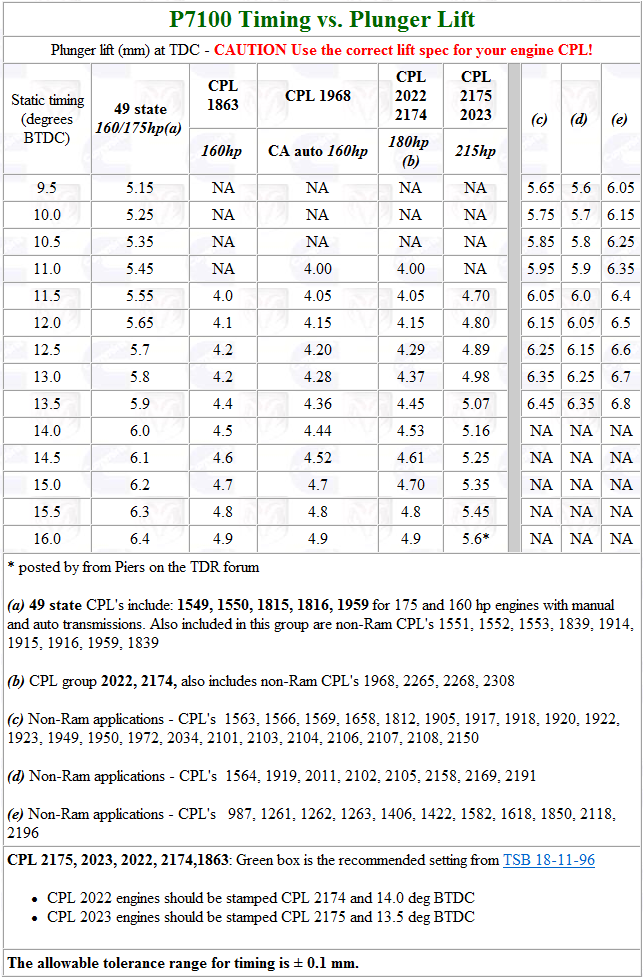

The 12V 5.9 Cummins engine has two timing marks: Top Dead Center (TDC): This mark is located on the harmonic balancer and indicates the position of the piston at the top of its stroke. Injection Pump Timing Mark: This mark is located on the injection pump and indicates the position of the pump at which fuel is injected into the cylinders.. To make 10 psi with advanced timing takes more fuel than 10 psi with retarded timing. You keep talking about the same amount of fuel being equal. But if you inject 100 mm3 of fuel at 14° it will have lower EGT 's, lower boost, and more hp than injecting 100 mm3 of fuel at 12°. EGT is not related to boost, not 100%.

Q&A 5.9 & 6.7 Cummins Timing Marks TDC for Dodge Diesel Injector Sprocket JustAnswer

Cummins 12 Valve cumminscams’s diary

Cummins Ism Torque Chart

HOW TO REMOVE SECOND GEN DODGE CUMMINS TIMING COVER EP.02 YouTube

12 Valve Cummins Fuel System Diagram General Wiring Diagram

diagram/schematic 5.9 12v Dodge Cummins Diesel Forum

12ValveCumminsHead04132017 Motor Mission Machine and Radiator

12 Valve Cummins Engine Diagram

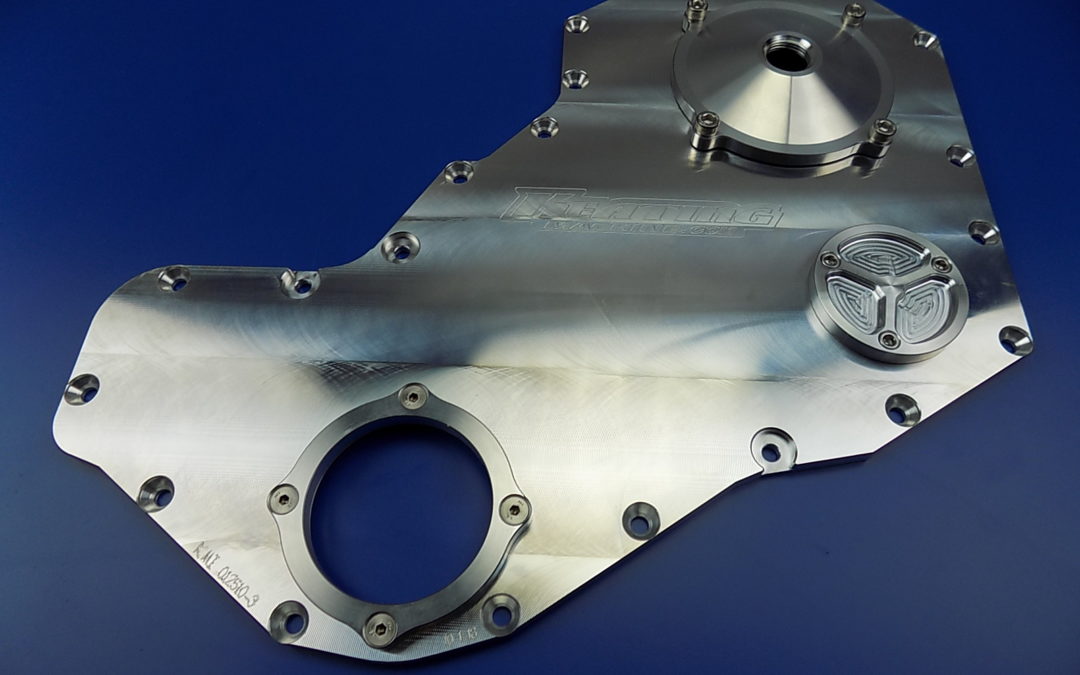

12 Valve Billet Timing Front Cover 5.9L fits Cummins Haisley Machine

How To Install Injectors On 12 Valve Cummins Specs priorityci

Cummins Timing Gears ubicaciondepersonas.cdmx.gob.mx

Valves Adjustment Cummins Diesel B Series Engines Operation and Maintenance

12 valve Cummins timing in 40 minutes part 1.mp4 YouTube

Adjusting timing Cummins Diesel Forum

12 Valve Cummins Timing P7100 Injection Pump Diagram & Pin Location

12 Valve Cummins Engine Wiring Diagram Uploadist

12 valve Cummins timing in 40 minutes part 3.mp4 YouTube

12V diagrams and then some Dodge Cummins Diesel Forum

Part 1 How to Rebuild a Cummins 12 Valve 5.9L Diesel Engine YouTube

VE Pump Timing Cummins Diesel Forum

5.9 mm. 13.5. Adjust Injection Pump Timing. 14. If a change in injection timing is required, remove the oil filler tube and adapter elbow from the front of the gear housing. 15. Place a magnet on the end of the shaft and remove the shaft nut (use the barring tool to keep the engine from rotating), (Figure 11).. However, a pump that's set at 18 to 20 degrees of timing advancement will see impressive gains. The 18 to 20-degree mark is the unofficial sweet spot for timing on a P-pumped Cummins in that it allows for good all-around power, drivability and cold-start performance. While considerably more power might be made with 25 or 26 degrees of timing.